INNOVATION SERVING THE COMPETITIVENESS OF SPANISH COMPANIES

Currently, coastal regions have become areas of vital importance to communities open to the sea, since they harbor the majority of their population and a large percentage of their economic activities depend on them.

“Innovating to achieve environmentally sound, safe and efficient technologies”

In this framework, maritime infrastructures become a key ingredient to encourage economic, social and territorial development in many countries. The development of sustainable, quality maritime infrastructure is essential to boost economic growth. As a result, Spanish companies such as Dragados and FCC Servicios Ciudadanos have made large investments in innovation to improve and optimize their construction processes and achieve the technological level required by the new infrastructures of the 21st century.

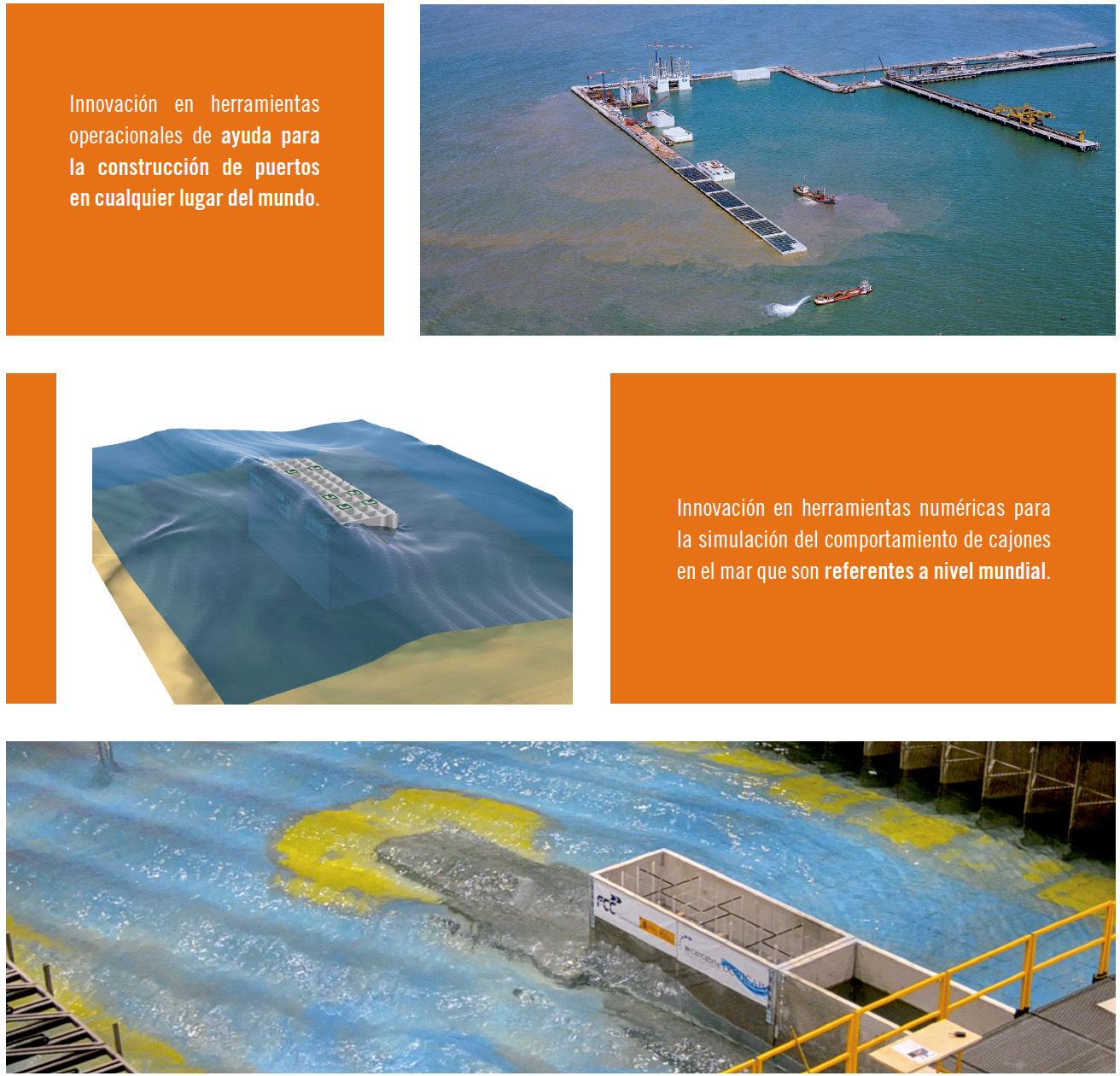

Among other innovative projects, IHCantabria has collaborated with both companies in the development of operational systems to support the construction of large maritime structures. The innovative systems yield short-term (up to 72 hours) numerical predictions for every meteoceanic variable that affects the construction process and integrate this information with the progress of the work, the method of construction used and the safety criteria in place for the various operations. The first one was developed for the Port of Langosteira, one of the largest port construction projects in Spain, lasting for a period of 5 years, and helped to considerably increase the efficiency and safety of the construction process.

In collaboration with FCC, IHCantabria developed an operational system that helped to build the Port of Açu, the largest in Latin America. This system was designed specifically for the specialized methods and construction techniques of FCC, which streamlined costs and increased safety at the site. The system generates specific daily work reports for transporting caissons from Rio de Janeiro to Açu, for constructing and anchoring the caissons and for building the cap block.

As an extension of this work, from 2014 to 2017, in collaboration with FCC, a methodology was developed to optimize the life cycle of concrete caissons, a highly competitive construction technique for building ports and protective structures. The result is a powerful numerical tool for modeling how floating concrete caissons behave at sea during the grouping, transport and anchoring phases. This tool has been calibrated and validated using the results of the laboratory campaign and the data extracted from field monitoring. This tool has excellent potential applications, not only for evaluating construction projects, but also for opening new technology markets and horizons by identifying operational and safety thresholds.